A torque wrench may seem like a fancy tool best left for the bike mechanics. But the truth is, you need it. It’s a small tool that anyone can learn to use by just looking at the manual. This tool has a vital role when it comes to bike safety. Speaking of safety, a Torque Wrench is handy in adjusting the bike’s bolt into specific tension.

As a result, you can prevent bolt snapping or damage on your bike’s delicate carbon body. Also, you can prevent fatal accidents when riding your bike due to poorly tightened bolts. Therefore, you can save a lot by owning a regular Torque Wrench.

What is a Torque Wrench used for?

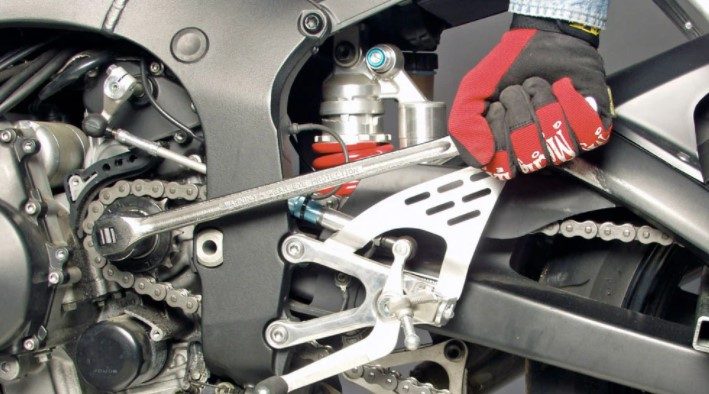

It’s a tool common among mechanics whether they are working on a bike, motorcycle, or vehicle mechanic. This tool is handy if you want an accurate adjustment of the nuts, screws, and bolts with the right torque. That said, it’s a precision gadget you can rely on for quality tightening. You need it to prevent breakage or deterioration of a clamping part due to inaccurate tightening.

Is There A Difference Between A Regular Torque Wrench And A Motorcycle Torque Wrench?

Regular torque wrenches are no different from motorcycle wrenches when it comes to the purpose and size of the drive. They are also applicable for different services whether you are fastening small, medium, or large nuts or bolts. However, the difference comes in on the size of torque and tension on the shaft.

The torque wrench for motorcycles is specifically designed to tackle the heaviest torque. As such, they can accommodate everything from large diameters of axle nuts and flywheels to the smallest bots on the engine case. So, if you are fastening motorcycle bots and nuts, get a torque wrench specifically for this role.

Can You Use A Regular Torque Wrench On A Bike?

The regular torque wrench is multipurpose when it comes to where it can be used. As long as you are adjusting a bolt, nut, or screw to a specific tension, you can use it. They often come in socket form with an internal mechanism that enables them to apply specific torque.

Since the bike comes with specific manufacturer recommendations on bolts and nut torque, a regular torque wrench is practical. You can use it in readjusting your bike’s bolts and nuts so that you can enjoy a comfortable and safe ride.

Types of Torque Wrenches

1. Click Torque Wrench

If you are familiar with Torque Wrenches, then you must have used the click type before. Among these tools, Click Torque Wrench is the most popular and commonly used for various projects. Also, it’s the most inexpensive option for those searching for a torque wrench on a budget.

Further, they are simple to use and even a novice on hands-on projects can tell how it works. And this is because they work as regular socket wrench. But the difference comes in when determining the precise torque. With the Click torque wrench, a click sound will pop when you reach the accurate tension.

On that note, Click type of wrench is an accurate tool that comes with multiple settings. The settings allow you to configure this tool according to the manufacturer’s recommendation of the bolt/nut you are tightening.

2. Digital Wrench

If the budget is not a concern and you need an accurate torque wrench that’s management, get a digital wrench. They come calibrated and have a digital screen where you can switch between various settings. As such, they are pricier than their counterparts. But, due to their speed and accuracy, they are common among professional mechanics.

On the digital screen, you can switch to a specific torque and adjust the bolt/nut accordingly. And since they are calibrated, you don’t have to worry about recalibration. On the positive end, you can work on several fastening projects with various tensions with ease. By pushing the button to set it, you can save time and complete your tasks fast.

3. Beam Type

Beam types are the most basic wrenches. It comes with a small gauge and two beams. One of the beams acts as an indicator of the torque you are applying on a bolt or nut. When you exert force on the handle, the beam moves to indicate the measurement on the gauge.

Unlike the click types, the Beam Type wrench leaves you in the dark when it reaches the precise tension. It doesn’t come with any signal but just measurement. Further, it doesn’t support a specific set of the tension you want to achieve on the nut/bolt. As such, you can say it’s the least accurate.

Even with the negative attribute, beam-type is a favorite among wrench buyers. It’s inexpensive and also manageable when using it. By tracking the beam pointer, you can tell whether you’ve reached the precise tension. While there are chances for error, it’s still a practical tool that can help you with various services.

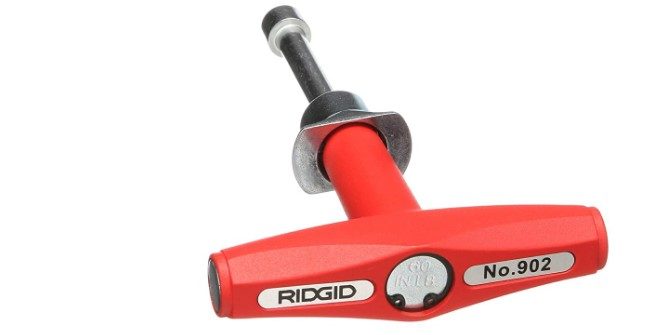

4. No Hub

This is the best pick for a portable wrench that you can use to manage your bike on the road. It can fit into your pocket due to its compact size, and it’s easier to use when the need comes. If you are riding a bike, you can use No hub to adjust the saddle bolts and seat post. Long-distance writing especially through rugged routes can exert strain on the bolts.

And these are opportunities where a No-hub wrench comes in useful. Besides mechanics, you can use this tool on house plumbing projects. And yes, you’ve heard it right. No-hub is resourceful in plumbing projects, especially when reaching out to tight spaces.

Conclusion

Back to our heading, can you use a regular torque wrench on a bike? Yes, it can apply. However, that doesn’t make it an ideal toolset. So, it’s important to consider the purpose and frequency of a particular torque wrench before deciding to get one. If you are working on a motorcycle, then a motorcycle torque wrench will do. Choose several sizes to ensure you can tackle most of the bolts and nuts. And the same applies when you are choosing this tool for a bicycle or even vehicle.